Short Pattern Flanged Control & Choke Valves

FDA Series

- Machined from solid bar stock; no porosity, limitless possible lengths

- Pressure ratings up to 10,000 psi MOP

- Xylan™ coated 17-4 stainless steel stem and disc driver

- Standard materials of API 4130 (75K) and 316SS, or customer-specified materials

- ANSI B16.34 and/or API 6A wall thickness and bolt loading

- Manual, electric, hydraulic or pneumatic actuation

- Open/close or modulating service

- Automated valves have selectable failure position

- Raised Face and RTJ flanges available

|

|

|

Size

Code |

Press

Code |

Disc

Type |

Size

(in) |

Pressure

Rating |

Max Ori

Size |

A

(in) |

B

(in) |

C

(in) |

D

(in) |

E

(in) |

F

(in) |

G

(in) |

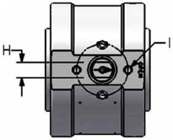

H

(in) |

I

(in) |

| 15 |

06 |

D2 |

1-1/2 |

CL 600 |

58/64 |

3.61 |

6.13 |

0.88 |

4.50 |

0.94 |

0.74 |

1.00 |

0.56 |

4 x .250-20 (1.75 BCD) |

| 18 |

10 |

D6 |

1-13/16 |

10K MOP |

91/64 |

6.73 |

7.88 |

0.88 |

5.75 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 20 |

06 |

D2 |

2 |

CL 600 |

58/64 |

5.00 |

6.50 |

0.75 |

5.00 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 20 |

06 |

D6 |

2 |

CL 600 |

91/84 |

5.00 |

6.50 |

0.75 |

5.00 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 20 |

15 |

D2 |

2 |

CL 1500 |

58/64 |

5.00 |

8.50 |

1.00 |

6.50 |

1.11 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 20 |

15 |

D6 |

2 |

CL 1500 |

91/64 |

5.00 |

8.50 |

1.00 |

6.50 |

1.11 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 20 |

62 |

D2 |

2 |

6250 MOP |

58/64 |

4.90 |

6.25 |

0.88 |

4.94 |

0.94 |

0.74 |

1.14 |

0.56 |

4 x .375-16 (2.50 BCD) |

| 21 |

10 |

D6 |

2-1/16 |

10K MOP |

91/64 |

6.73 |

7.88 |

0.88 |

6.25 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 29 |

50 |

D9 |

2-9/16 |

5K MOP |

120/64 |

6.19 |

9.62 |

1.00 |

7.25 |

1.20 |

1.12 |

1.44 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 30 |

06 |

D6 |

3 |

CL 600 |

91/64 |

5.00 |

8.25 |

0.88 |

6.62 |

1.27 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 30 |

06 |

D9 |

3 |

CL 600 |

120/64 |

5.75 |

8.25 |

0.88 |

6.62 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 30 |

15 |

D6 |

3 |

CL 1500 |

91/64 |

6.00 |

10.50 |

1.25 |

8.00 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 30 |

25 |

D9 |

3 |

CL 2500 |

120/64 |

5.06 |

12.00 |

1.38 |

9.00 |

1.20 |

1.12 |

1.40 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 30 |

09 |

D2 |

3 |

CL 900 |

58/64 |

5.00 |

9.50 |

1.00 |

7.50 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 30 |

09 |

D6 |

3 |

CL 900 |

91/64 |

5.00 |

9.50 |

1.00 |

7.50 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 31 |

10 |

D9 |

3-1/16 |

10K MOP |

120/64 |

7.40 |

10.62 |

1.12 |

8.50 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 40 |

06 |

D6 |

4 |

CL 600 |

91/64 |

5.60 |

10.75 |

1.00 |

8.50 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 40 |

06 |

D9 |

4 |

CL 600 |

120/64 |

5.60 |

10.75 |

1.00 |

8.50 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 40 |

09 |

D6 |

4 |

CL 900 |

91/64 |

6.06 |

11.50 |

1.25 |

9.25 |

1.20 |

1.12 |

1.30 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 40 |

09 |

D9 |

4 |

CL 900 |

120/64 |

6.06 |

11.50 |

1.25 |

9.25 |

1.20 |

1.12 |

1.30 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 40 |

15 |

D6 |

4 |

CL 1500 |

91/64 |

6.06 |

12.25 |

1.38 |

9.50 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

| 40 |

15 |

D9 |

4 |

CL 1500 |

120/64 |

6.10 |

12.25 |

1.38 |

9.50 |

1.20 |

1.12 |

1.50 |

0.75 |

4 x .375-16 (2.50 BCD) |

In order to consistently offer you the highest quality, fully engineered products, we reserve the right to change our specifications and designs at any time. Cyclonic Valve products and the Cyclonic logo are registered and/or common law trademarks of Cyclonic Valve Company. This document, including textual matter and illustrations, is copyright protected by Cyclonic Valve Company, with all rights reserved ©2026 Cyclonic Valve Company.